Boot Loader Meaning

The boot loader meaning refers to a small startup firmware stored in protected flash that executes immediately after reset. In an embedded device, the bootloader runs before the application firmware and verifies whether the system is safe to start. Unlike a PC where a boot loader windows or BIOS performs startup, an embedded controller depends entirely on the bootloader.

What Is Embedded Bootloader?

An embedded bootloader is the foundation of every industrial product. The bootloader in embedded system handles reset vector execution, basic hardware initialization, firmware validation, update control, and application jump. In production devices, the bootloader is permanently stored in protected memory and is never overwritten.

Embedded Boot Process

The boot process in a microcontroller-based system typically follows this sequence:

- Reset Vector Execution – After power-on or reset, the CPU fetches the reset vector address from a predefined memory location.

- Boot loader Startup – The boot loader initializes essential hardware such as clocks, stack pointer, and basic peripherals.

- System Validation – The boot loader may verify firmware integrity, version information, or digital signatures.

- Update Decision – Based on conditions (communication request, GPIO state, or firmware validity), the boot loader decides whether to enter update mode or start the application.

- Application Jump – Control is transferred to the main firmware by setting the stack pointer and jumping to the application reset handler.

This deterministic flow ensures predictable system behavior even in failure scenarios.

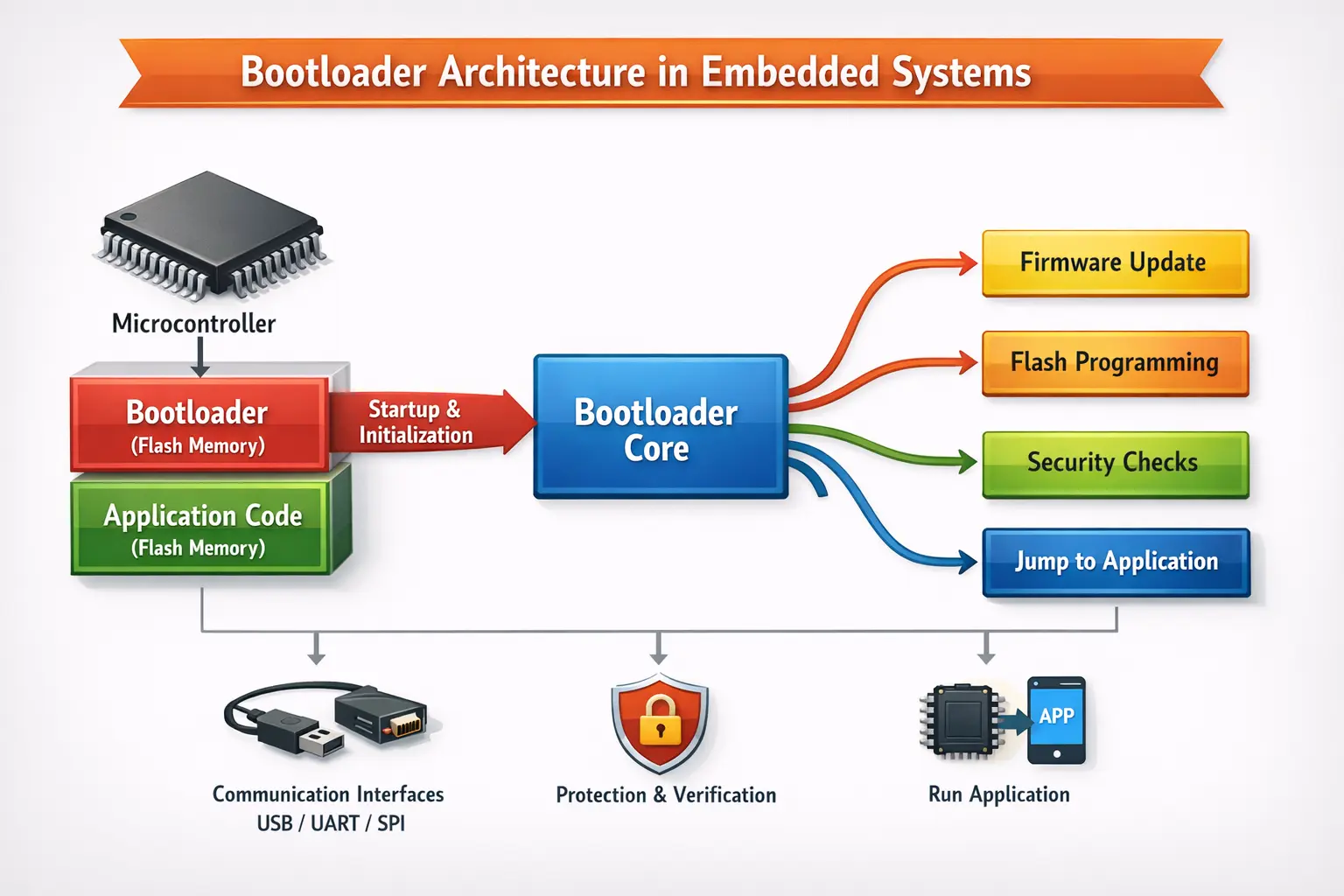

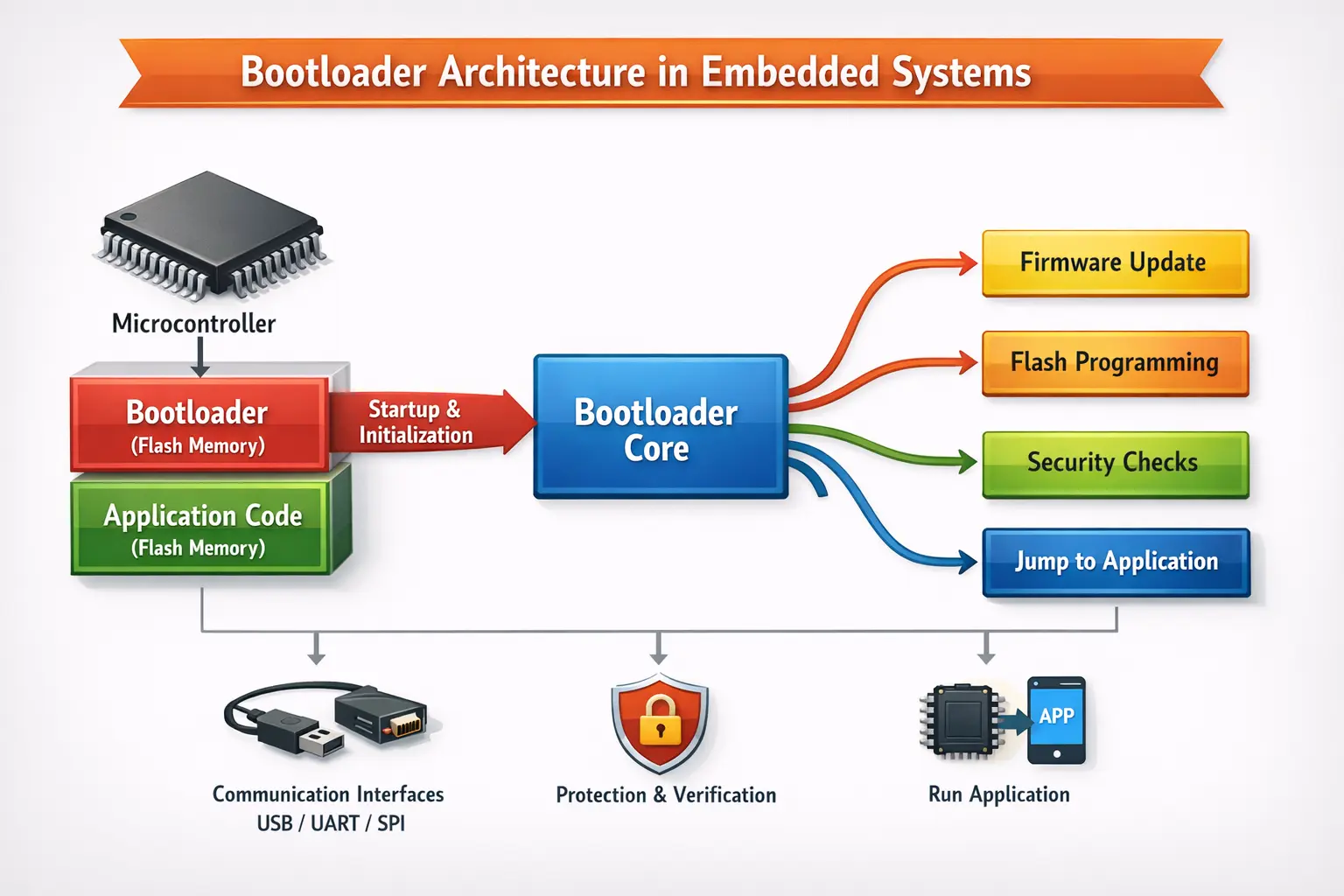

Bootloader Architecture in Embedded Systems

Memory layout is a key design consideration in boot loader development. Typically, embedded flash memory is divided into regions:

- Boot loader Region – Occupies the initial flash sectors and is often write-protected.

- Application Region – Contains the main firmware image.

- Metadata or Configuration Region – Stores version information, flags, or update status.

A professional boot loader must be carefully sized to minimize flash usage while still providing essential functionality. Poor memory planning can limit future firmware upgrades or compromise system reliability.

Firmware Update Using Bootloader

One of the primary motivations for using a boot loader is enabling firmware updates without external programmers. Advanced embedded systems support multiple update strategies:

- UART / USB Boot loading – Common in development and factory environments.

- CAN, Ethernet, or RS-485 Updates – Used in industrial and automotive systems.

- Wireless Updates (OTA) – Implemented using Bluetooth, Wi-Fi, or cellular modules.

A robust boot loader includes fail-safe mechanisms such as dual-image support or rollback protection to prevent system bricking during interrupted updates.

Bootloader Execution Flow

The bootloader execution flow defines how a system transitions from reset to application.

- Hardware setup

- Firmware integrity check

- Update mode decision

- Application jump

Any error in the bootloader execution flow can permanently brick the device.

Bootloader Responsibilities

The bootloader responsibilities are intentionally minimal:

- Hardware initialization

- Firmware authentication

- Update handling

- Jump to firmware

All business logic must remain in application code. Keeping the bootloader in embedded system small ensures stability.

Bootloader vs Application Firmware

Understanding bootloader vs application firmware separation is critical. The bootloader in embedded system must never contain communication stacks, RTOS logic, or control algorithms. It only provides the safe startup layer.

Boot Loader Design in Embedded System

A proper boot loader design in embedded system must include:

- Flash protection

- Version management

- Safe update rollback

- Communication error recovery

Weak boot loader design is the number one cause of field failures.

Bootloader in Microcontroller

The bootloader in microcontroller based platforms such as STM32, PIC, AVR, and MSP430 is the backbone of production firmware management. In these devices, the bootloader in embedded system is responsible for receiving new firmware images through UART, USB, CAN, or SPI and safely programming internal flash memory.

A well-designed bootloader for microcontrollers includes memory erase control, page-wise flash programming, checksum validation, and fallback handling. Even a basic implementation significantly reduces manufacturing costs by eliminating external programmers and enabling in-field updates across thousands of deployed units.

Bootloader in Automotive

The automotive bootloader system is a mission-critical implementation of the bootloader in embedded system. Modern vehicles contain over 70 ECUs, each requiring secure and reliable firmware upgrades.

The bootloader in automotive systems supports UDS diagnostics, CAN-FD data transfer, secure key exchange, and rollback-safe update mechanisms. If an update is interrupted due to ignition loss or power fluctuation, the bootloader restores the previous firmware version to prevent ECU failure — a non-negotiable safety requirement in automotive electronics.

Industrial Bootloader Applications

In manufacturing plants, industrial bootloader applications control PLCs, robotics controllers, motion drives, and safety modules. The bootloader in embedded system here enables scheduled firmware rollouts across entire production lines without halting operations. Industrial bootloaders support RS-485, Ethernet, Modbus, and PROFINET communication stacks and integrate strong CRC validation. A corrupted or missing bootloader embedded system can result in production downtime costing lakhs per hour, making robustness and recovery strategies absolutely critical.

Professional Bootloader Development

Professional bootloader development goes far beyond simple flashing routines. Engineers must account for flash endurance limits, hardware revision mismatches, backward compatibility, cryptographic signing, and update atomicity.

A production-ready bootloader must survive power loss, EMI noise, memory corruption, and incorrect firmware images while always guaranteeing a recoverable state.

Bootloader in Mobile Devices and Bootloader Unlocking

Smartphones use a highly secured variant of the embedded bootloader system that controls the entire Android startup chain. Devices such as:

- bootloader Samsung A12

- bootloader Samsung A50

- bootloader Samsung A51

- bootloader Samsung S7 / S8 / S21

- bootloader Poco X3 Pro

- bootloader Redmi Note 8 / 8 Pro / 10 / 10 Pro / 11

Bootloader Unlock Process

In Android devices, unlocking the bootloader removes OEM restrictions, allowing flashing of custom ROMs or kernels. However, when a bootloader unlocked state is detected:

- Secure boot is disabled

- DRM services are revoked

- Device integrity checks fail

- Warranty may be voided

This mechanism is implemented using hardware root-of-trust, making the mobile bootloader in embedded system one of the most advanced security implementations in consumer electronics.

Common Bootloader Design Challenges

- Limited flash and RAM availability

- Handling interrupted firmware updates

- Maintaining backward compatibility

- Supporting multiple hardware revisions

- Ensuring long-term field upgradability

Addressing these challenges early in the design phase significantly improves product reliability and maintainability.

Security in Bootloader

Modern devices face attacks where firmware is tampered. The bootloader in embedded system prevents this using:

- Secure boot

- Firmware authentication

- Flash write protection

- Anti-rollback protection

These mechanisms prevent unauthorized access even when the device is physically compromised.