The Single Wire Interface (SWI) is a communication protocol that employs a single data line for the purpose of transmitting data in a serial manner. It is often utilized in applications that prioritize low power usage and cost efficiency, particularly where minimizing the number of wires and power consumption is crucial. It operates using a half-duplex protocol, allowing data to be sent in both directions, though not simultaneously.

SWI implements bit stuffing strategies for clock synchronization and supports an array of data formats, including I2C, SPI, and UART. The protocol is both simple and efficient, relying on just one signal line for data transfer. This feature renders it an excellent option for various applications, such as smart cards, sensors, and low-power microcontrollers.

The Core Principles Governing SWI

During the transmission of data via SWI, the data line shifts between high and low states to represent the initiation and termination of each bit. Both the transmitter and receiver achieve synchronization by measuring the bit count that exists between the start and stop bits. To ensure timing synchronization, a “stuff bit” is added when a data bit is not transmitted for a predetermined number of clock cycles.

SWI features a native error detection mechanism designed to ensure the correct transmission of data. This approach incorporates the addition of a checksum at the end of each data byte, which functions to validate the integrity of the transmitted information.

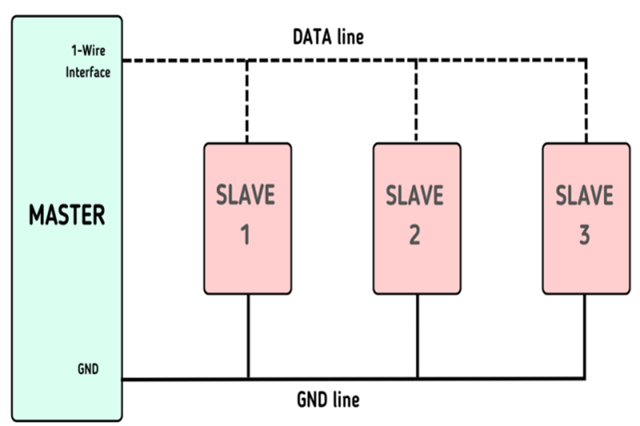

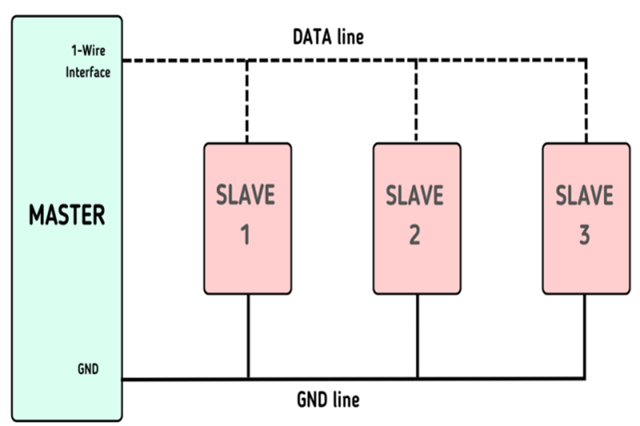

Mechanism of the Multi Slave Protocol

SWI allows for the connection of multiple slave devices to a single bus, typically represented by a single wire. The communication process is initiated by the master device, which sends a start signal and subsequently transmits a command packet aimed at a specific slave device. The slave device that has been addressed responds by sending an acknowledgment signal, after which the master device transmits the data packet. Once the data packet is received, the intended slave device issues an acknowledgment signal to signify that it has obtained the data.

In a scenario where multiple slave devices are attached to the bus, the master device is able to communicate with each one by referencing their unique addresses. The controlling device issues the start signal, subsequently providing the address of the slave device it aims to interact with. Upon receiving the acknowledgment signal from the specified slave device, the master device proceeds to send a command packet or a data packet.

By utilizing this method, the master device is capable of communicating with numerous slave devices over a single wire. To ensure reliable communication between master and slave devices, the SWI protocol features error detection and correction mechanisms. The SWI protocol is widely recognized in various industries due to its effectiveness in managing multiple devices through a single wire connection.

Merits of Adopting SWI

- SWI facilitates easier implementation and interfacing relative to other interfaces, such as I2C, by employing a single wire connection and not requiring a distinct clock.

- The use of differential signals allows for interfacing over greater distances, with a maximum range of 300 meters.

- By utilizing only two wires, this interface type enables access to several slaves, thereby improving efficiency.

- The implementation of SWI necessitates fewer wires, contributing to a tidier circuit layout.

Limitation of Employing SWI:

- There is a scarcity of SWI manufacturers, as Dallas Semiconductors stands as the only producer in the market.

- SWI can support extended distances; however, its effectiveness is compromised by noise and the capacitance of the cables.

- The speed of communication transmission and reception is inferior to that of alternative interfaces.

- Due to the lack of standardization in SWI, achieving compatibility between devices from different manufacturers becomes difficult, unlike the more standardized I2C or SPI protocols.

- A restricted volume of data can be sent simultaneously, thereby limiting its operational capabilities.

Deployment of SWI

As a communication protocol, the Single Wire Interface (SWI) finds extensive use in various applications across different sectors. The automotive industry employs SWI to facilitate the connection of sensors and devices in vehicles, leveraging its proficiency in managing numerous devices with just one wire. With its low energy consumption and simple integration, the protocol is particularly advantageous for devices powered by batteries, including wearables and IoT applications. In the realm of industry, SWI is employed in the manufacturing process to monitor and control machinery, gather data, and transmit it to a centralized location for analytical purposes. Within the medical field, SWI serves a purpose in patient surveillance and home healthcare equipment. SWI stands out as a highly suitable communication protocol for numerous applications due to its flexibility, minimal power usage, and cost-effectiveness.