One of the fundamental aspects of industrial automation is the seamless connectivity of devices and systems. AWS IoT acts as a bridge, allowing disparate devices to communicate, share data, and work in tandem. With AWS IoT, organizations can integrate a myriad of sensors, machines, and other industrial devices into a unified network. This interconnected ecosystem facilitates real-time data exchange, providing a comprehensive view of the entire industrial process.

Real-time Data Analytics:

Industrial automation relies heavily on data-driven decision-making. AWS IoT provides powerful analytics tools that enable organizations to derive valuable insights from the vast amount of data generated by connected devices. Amazon Kinesis, a fully managed service for real-time data streaming, allows businesses to process and analyze data in real-time. This capability is crucial for identifying patterns, predicting equipment failures, and optimizing processes.

Moreover, AWS IoT Analytics simplifies the process of transforming raw data into actionable information. By leveraging features such as data filtering, enrichment, and transformation, organizations can create meaningful dashboards and reports, facilitating informed decision-making at every level of the operation.

Secure and Scalable Infrastructure:

Security is paramount in industrial automation, especially as more devices become connected. AWS IoT addresses this concern by providing a secure and scalable infrastructure. Device communication is protected through industry-standard security protocols, ensuring data confidentiality and integrity. AWS IoT also offers device management services that enable organizations to control, monitor, and update connected devices securely.

Furthermore, AWS IoT’s scalable architecture allows businesses to adapt to changing requirements effortlessly. Whether an organization is expanding its operations or dealing with varying workloads, AWS IoT can seamlessly scale to accommodate the evolving needs of industrial automation.

Edge Computing for Low-Latency Processing:

In industrial automation, low-latency processing is often critical for timely decision-making. AWS IoT extends its capabilities to the edge through AWS IoT Greengrass, enabling devices to perform local computing and processing. This reduces the need to send all data to the cloud, resulting in lower latency and improved response times.

AWS IoT Greengrass also facilitates offline operation, ensuring that devices can continue to function even in the absence of a reliable internet connection. This is particularly beneficial for industrial environments where network connectivity may be intermittent.

Predictive Maintenance:

One of the key advantages of implementing AWS IoT in industrial automation is the ability to implement predictive maintenance strategies. By continuously monitoring the condition of equipment through sensors and analyzing the data in real-time, organizations can predict when machinery is likely to fail. This proactive approach helps prevent costly unplanned downtime and extends the lifespan of industrial assets.

AWS IoT integrates seamlessly with machine learning services such as Amazon SageMaker, enabling organizations to build and deploy predictive maintenance models. These models can analyze historical data, identify patterns indicative of impending failures, and trigger maintenance actions before a breakdown occurs.

Cost Optimization:

AWS IoT provides a cost-effective solution for industrial automation by offering a pay-as-you-go pricing model. Organizations only pay for the resources they use, allowing for flexibility and cost optimization. This is particularly advantageous for small and medium-sized enterprises looking to adopt IoT solutions without significant upfront investments.

Additionally, the scalability of AWS IoT ensures that businesses can align their expenses with their operational needs. As the number of connected devices grows, AWS IoT scales accordingly, preventing overprovisioning and unnecessary costs.

Integration with Other AWS Services:

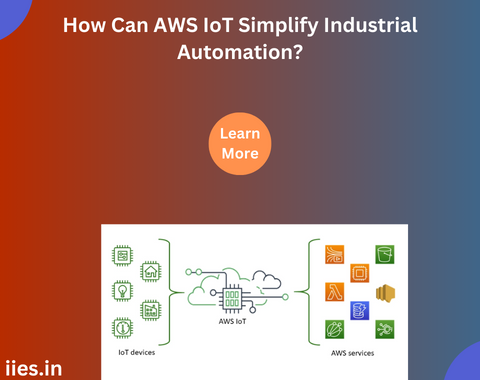

AWS IoT seamlessly integrates with a plethora of other AWS services, providing organizations with a comprehensive ecosystem for industrial automation. For instance, Amazon S3 (Simple Storage Service) can be utilized for storing and archiving vast amounts of data generated by IoT devices. This ensures that historical data is readily available for analysis and compliance purposes.

Moreover, AWS Lambda, a serverless computing service, can be employed to execute code in response to specific IoT events. This serverless architecture enhances the scalability and agility of industrial automation solutions, allowing organizations to focus on developing innovative applications rather than managing infrastructure.

Customization and Flexibility:

Industrial processes vary across sectors and organizations, demanding flexibility in IoT solutions. AWS IoT offers a customizable platform that allows businesses to tailor their IoT implementations to specific requirements. From defining data processing workflows to creating custom device management policies, AWS IoT provides the flexibility needed to adapt to diverse industrial scenarios.

Compliance and Certification:

Industries such as healthcare, manufacturing, and energy are often subject to stringent regulations and standards. AWS IoT aids organizations in meeting compliance requirements by offering built-in security features and facilitating adherence to industry-specific certifications.