Importance of Communication Protocols in Microcontroller Systems

In embedded systems, communication protocols determine how microcontrollers exchange data with peripherals and controllers. They influence:

- Data transfer speed

- Number of connected devices

- Error detection and recovery

- System reliability in noisy environments

An incorrect protocol choice can cause data corruption, timing failures, EMI issues, and poor scalability. Understanding embedded communication protocols is essential for robust system design.

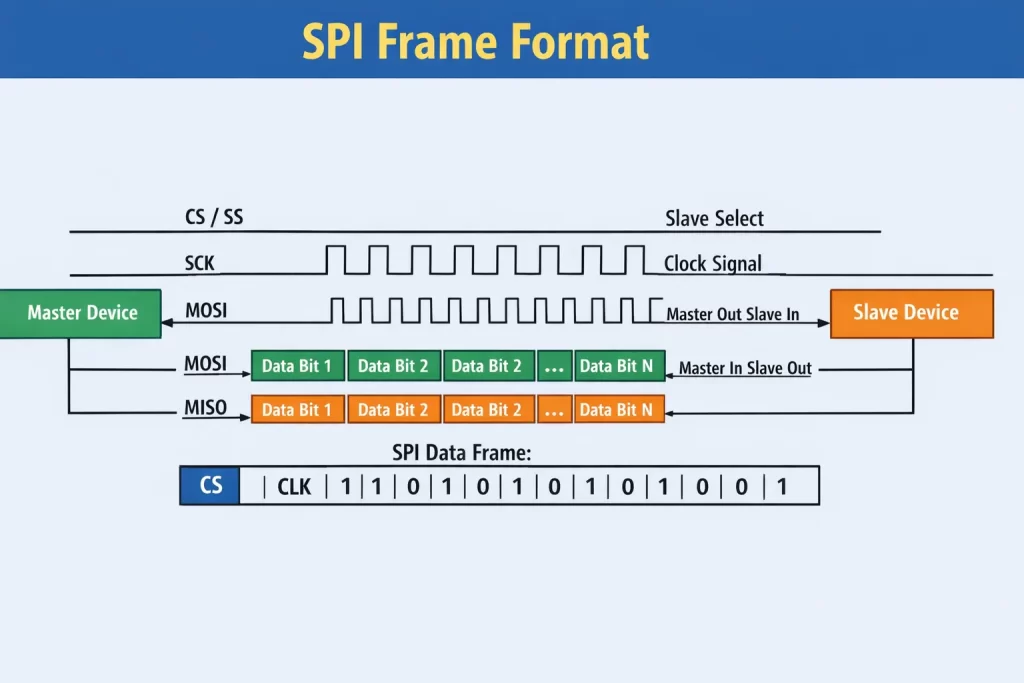

SPI Communication Protocol in Microcontrollers

SPI (Serial Peripheral Interface) is a synchronous, full-duplex protocol used for high-speed, short-distance data transfer.

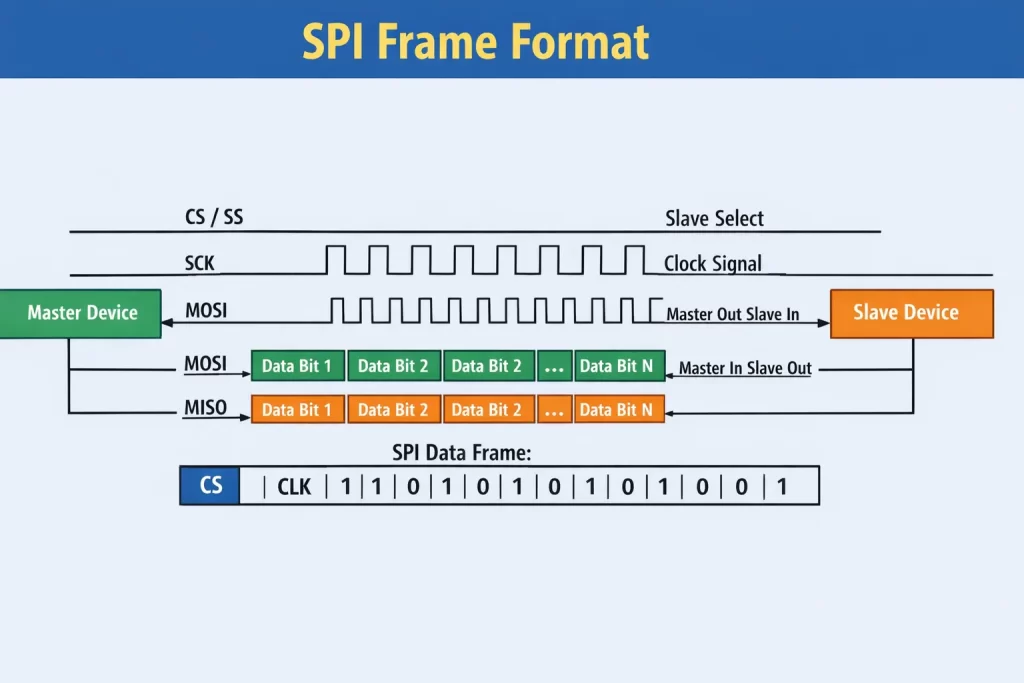

SPI Architecture and Signal Lines

- MOSI – Master Out Slave In

- MISO – Master In Slave Out

- SCK – Serial Clock

- SS / CS – Slave Select / Chip Select

SPI Data Transmission Mechanism

- Master and slave use shift registers

- Data is transmitted and received simultaneously

- Common word lengths are 8-bit or 16-bit

SPI Timing Modes (CPOL / CPHA)

SPI supports four timing modes defined by Clock Polarity (CPOL) and Clock Phase (CPHA).

Advantages of SPI

- Very high data rates (tens of Mbps)

- Full-duplex communication

- Low latency

Disadvantages of SPI

- More GPIO pins required

- No built-in addressing or error checking

- Short communication distance

Typical SPI Use Cases

- SD cards, Flash memory

- Displays, ADCs, DACs

- Camera modules

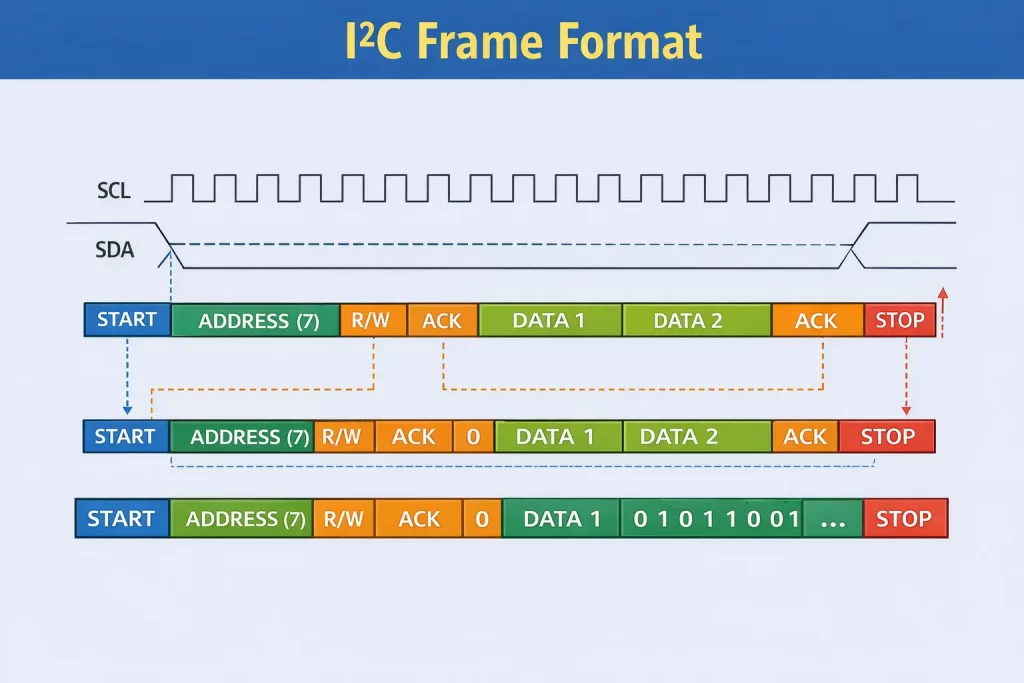

I²C Communication Protocol in Microcontrollers

I²C (Inter-Integrated Circuit) is a two-wire, half-duplex protocol for low-speed peripheral communication.

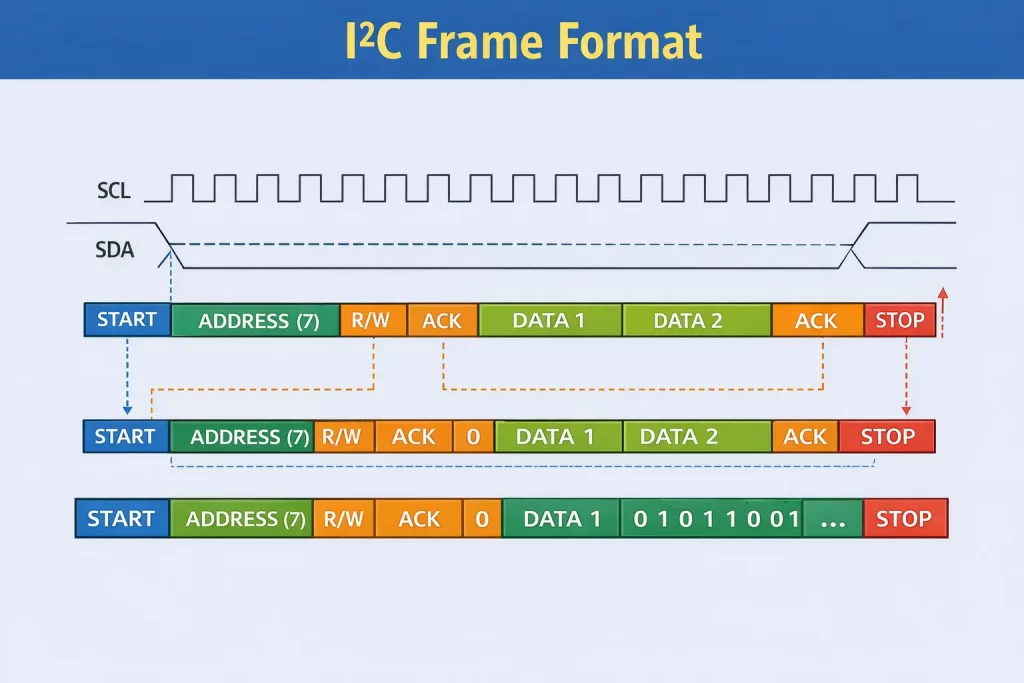

I²C Architecture and Signal Lines

- SDA – Serial Data

- SCL – Serial Clock

Addressing and Bus Conditions

- 7-bit and 10-bit addressing

- START and STOP conditions

- ACK / NACK after every byte

I²C Frame Format

START → Address + R/W → ACK → Data → ACK → STOP

Advantages of I²C

- Only two wires required

- Built-in addressing

- Low hardware cost

Limitations of I²C

- Slower (100 kHz – 3.4 MHz)

- Limited distance (< 1 m)

- Pull-ups limit scalability

Typical I²C Use Cases

- Sensors, EEPROM, RTC

- Power-management ICs

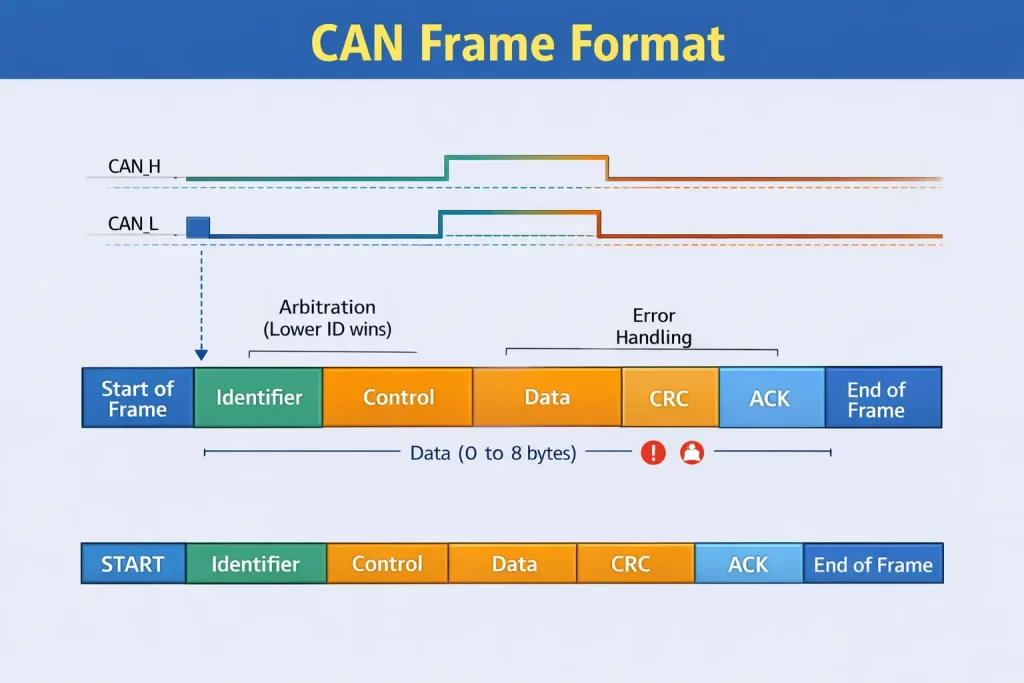

CAN Communication Protocol in Embedded Systems

CAN (Controller Area Network) is a multi-master, message-based protocol for noisy environments.

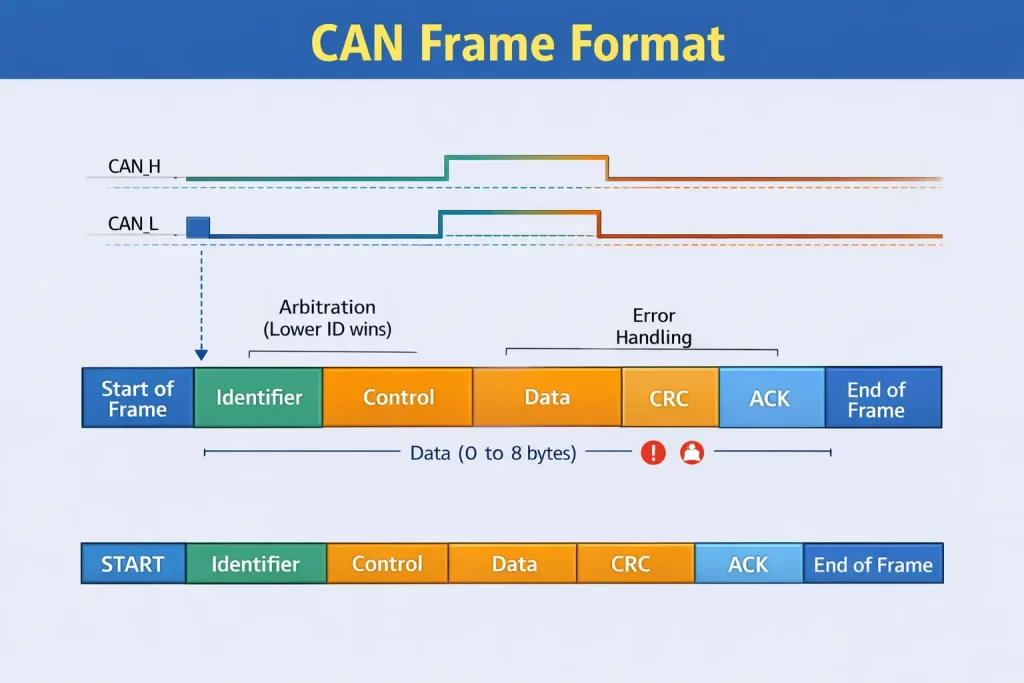

CAN Architecture and Signaling

- Differential signaling (CAN_H, CAN_L)

- Uses message identifiers instead of addresses

- External CAN transceivers required

CAN Frame Format

- Start of Frame

- Identifier (11 / 29-bit)

- Control Field

- Data Field

- CRC

- ACK

- End of Frame

Arbitration and Error Handling

- Priority arbitration (lower ID = higher priority)

- Automatic retransmission

- Error-passive and bus-off states

Advantages of CAN

- High reliability

- Excellent noise immunity

- Long distance (up to ~1 km)

Limitations of CAN

- More complex protocol

- Extra hardware required

- Lower speed than SPI

SPI vs I²C vs CAN Comparison

| Feature | SPI | I²C | CAN |

|---|

| Type | Full-duplex | Half-duplex | Differential |

| Wires | 4+ | 2 | 2 |

| Speed | ~50 Mbps | 3.4 Mbps | 1–5 Mbps |

| Distance | Short | Short | Long |

| Error Handling | None | ACK/NACK | CRC + Retransmission |

How to Choose the Right Communication Protocol

Choose SPI if:

- High data throughput is required

- Low latency is critical

- Devices are close to the microcontroller

Choose I2C if:

- Multiple low-speed devices share a bus

- Minimal wiring is required

- Communication is non-critical

Choose CAN if:

- Reliability is more important than speed

- Long cable lengths are involved

- The environment is noisy or safety-critical

Quick rule:

Speed → SPI

Simplicity → I2C

Reliability → CAN

Standards, Specifications, and Compliance References

The communication protocols discussed are governed or influenced by internationally recognized standards:

- SPI: Widely adopted de-facto standard implemented consistently by manufacturers such as Microchip, STMicroelectronics, NXP, and Texas Instruments.

- I²C: Officially specified and maintained by NXP Semiconductors, defining electrical, timing, and addressing requirements.

- CAN: Standardized under the ISO 11898 family of standards and originally developed by Bosch, making it suitable for automotive and industrial systems worldwide.

Designing according to these specifications ensures interoperability, robustness, and long-term reliability.

Real-World Usage Examples

- SPI: Displays, SD cards, ADCs

- I2C: Sensors, EEPROMs, RTCs

- CAN: Automotive ECUs, industrial controllers

Conclusion

There is no single communication protocol that fits all embedded applications.

- SPI is ideal for high-speed data transfer

- I²C is best for simple, low-cost peripheral connections

- CAN excels in reliable, long-distance, and safety-critical systems

A solid understanding of SPI, I2C, and CAN communication protocols enables engineers to design efficient, scalable, and reliable embedded systems.